Many years ago (2008) I started roasting my own coffee. At first, I simply put it in an air popper and let it go. It burned the beans on the outside and left the inside under-roasted. (ie, still green) BUT, it was the best cup of coffee I had ever tasted. I was hooked. I read more and more about temperatures and profile curves and first and second crack. I bought a temperature probe and dropped it in the air popper while I roasted beans. I controlled the temperature by plugging in and unplugging the popper. Next, I plugged it into a power bar with a switch, so I could just turn it on and off rather than plugging and unplugging.

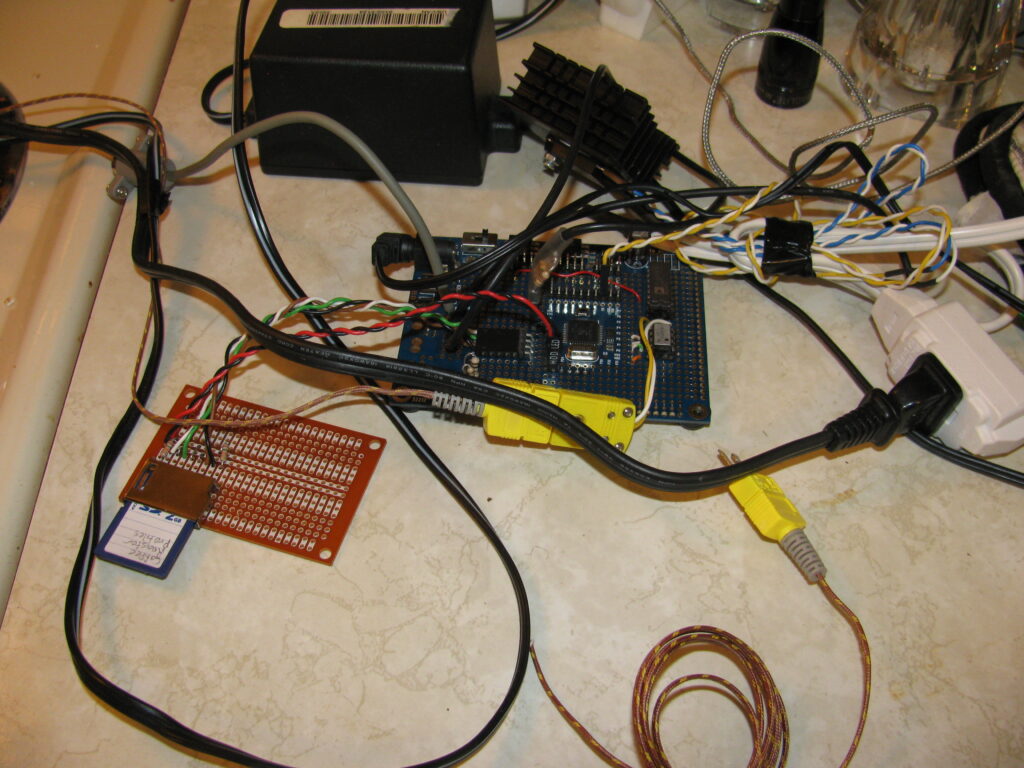

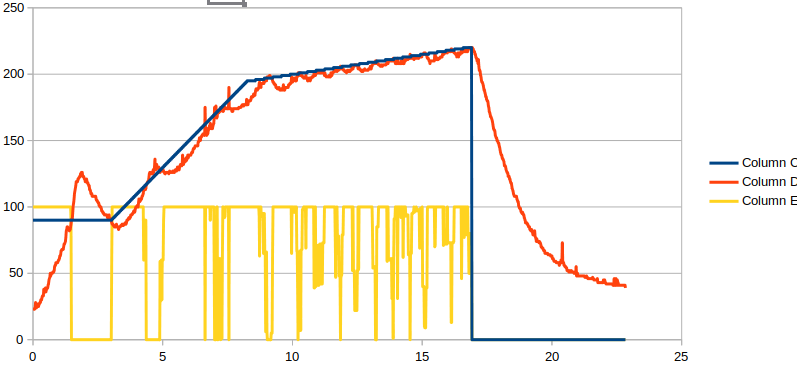

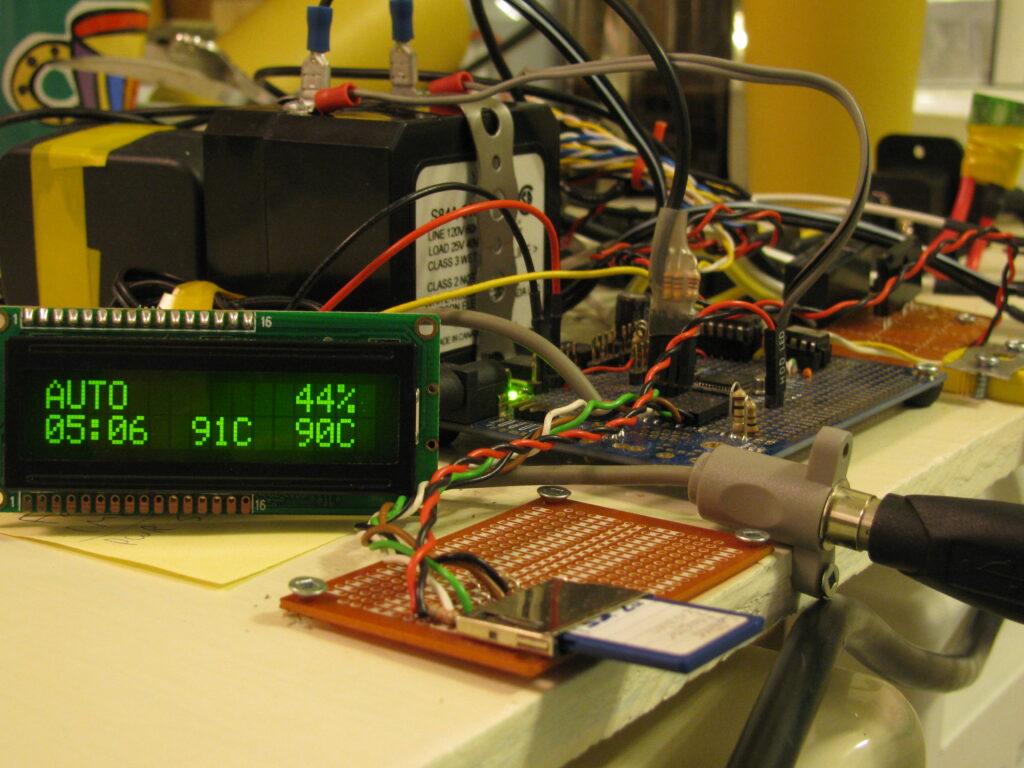

I’m an electronics guy with a microcontroller and controls background. I thought, this is silly. Why don’t I automate this? So I did.

It worked great! I started ordering different varieties of green beans and developed roasts for each one. I made a few improvements over time, and the system worked great. With one exception.

Air poppers aren’t made for the temperatures and durations that I was running them for. The motors would burn out and I was constantly buying new (or used) poppers and rewiring them. (These weren’t stock by this time. I had separate control over the heating element and the fan.) Not all poppers were the same inside and not all could be modified for my purpose. After a bad run of already-worn-out poppers from Value Village, I bought some replacement motors direct from China. I figured it would be easier to simply swap motors than to rewire a whole new popper. I figured new motors would last longer than garage sale poppers. The China motors didn’t work well, either. I was getting frustrated. So, in 2015, I broke down and purchased a small commercially produced coffee roaster. Excited about my new purchase, I dumped in 150g of green beans (less than my air-popper ones would do) that the manual said to and turned it on. It had basically one setting. “On.” (and a timer) It burned the beans on the outside and left them raw on the inside.

I took the thing apart to see if I could re-program it. It used a very cheap 8051 micro. Maybe I could do something. BUT, it used a capacitive dropper to produce the power for the micro, and the micro floated up near “line” from mains. (Vcc is 120V AC Line and “GND” rides 5V below that.) Not wanting to kill myself, I packed the thing up and left it in a box for 9 years.

I recently pulled it out and tried to figure out how I could modify it again. It uses a “clever” circuit something like an old-school light dimmer to produce the voltage for the fan. This circuit rides up near Line, so I really don’t want to directly connect my own system to that. I would have to use optoisolators to interface to the fan and heater control. It could be done. It won’t be a quick job.

But, how bad was it really? It has been a long time. (and I have been roasting my coffee in a cast iron frying pan on the stove top. Yes, that actually works. Not well, but it works.)

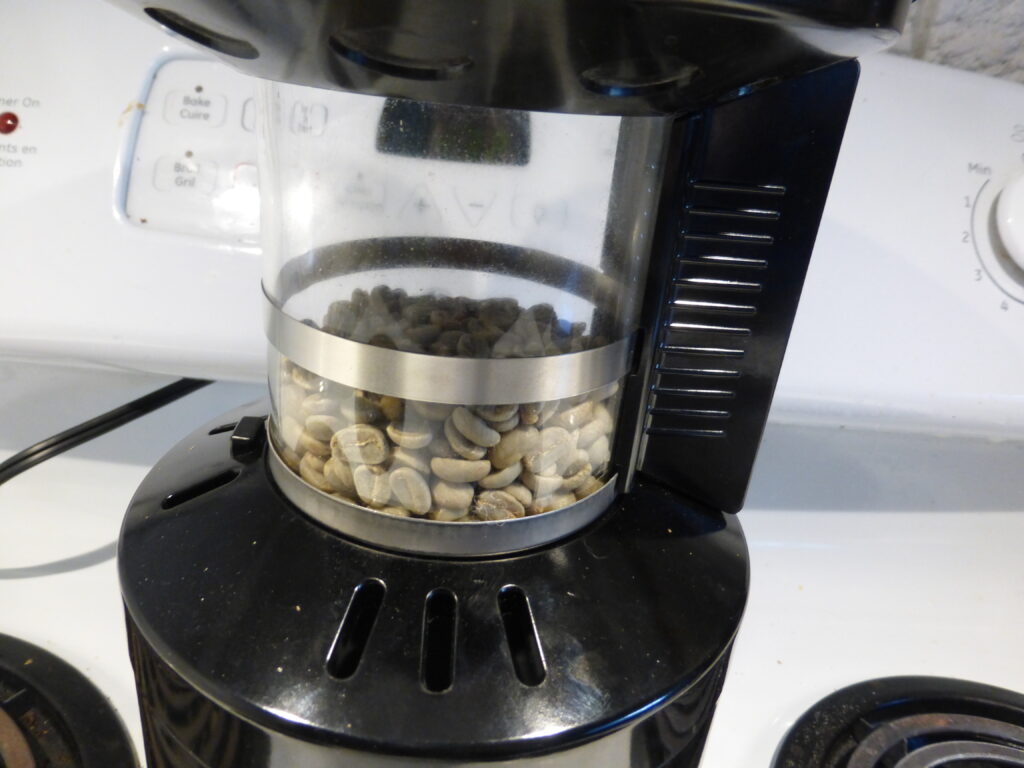

I figured I should try it once more before hiding it away again. I had already read online that 150g was too large of a load for this roaster. It was suggested to start at 120g instead. (the beans won’t “stir” themselves if there are too many, and then the ones near the bottom will burn while the ones near the top stay raw) I loaded up 120g and hit go.

Even at 120g it wasn’t stirring as much as I would like at the start of the roast. Also, (and this is really a personal preference) it went WAY into 2nd crack before ending the roast and beginning the cooldown. The timer defaults to 5.9 minutes. I decided to try again with 110g of beans and only 4.9 minutes. This still went well into 2nd crack. (I like my beans just shy of 2nd crack.) It wasn’t terrible, so I tried one more batch of 110g and only let them run 4.2 minutes. These actually don’t look terrible. But that’s a VERY fast roast. My profiles would take 15 minutes to reach 2nd crack. This thing still runs WAY too hot. But it’s not as bad as I remembered, so I might use it for a while until I get frustrated enough to build my own control system for it. 🙂

Leave a Reply

You must be logged in to post a comment.